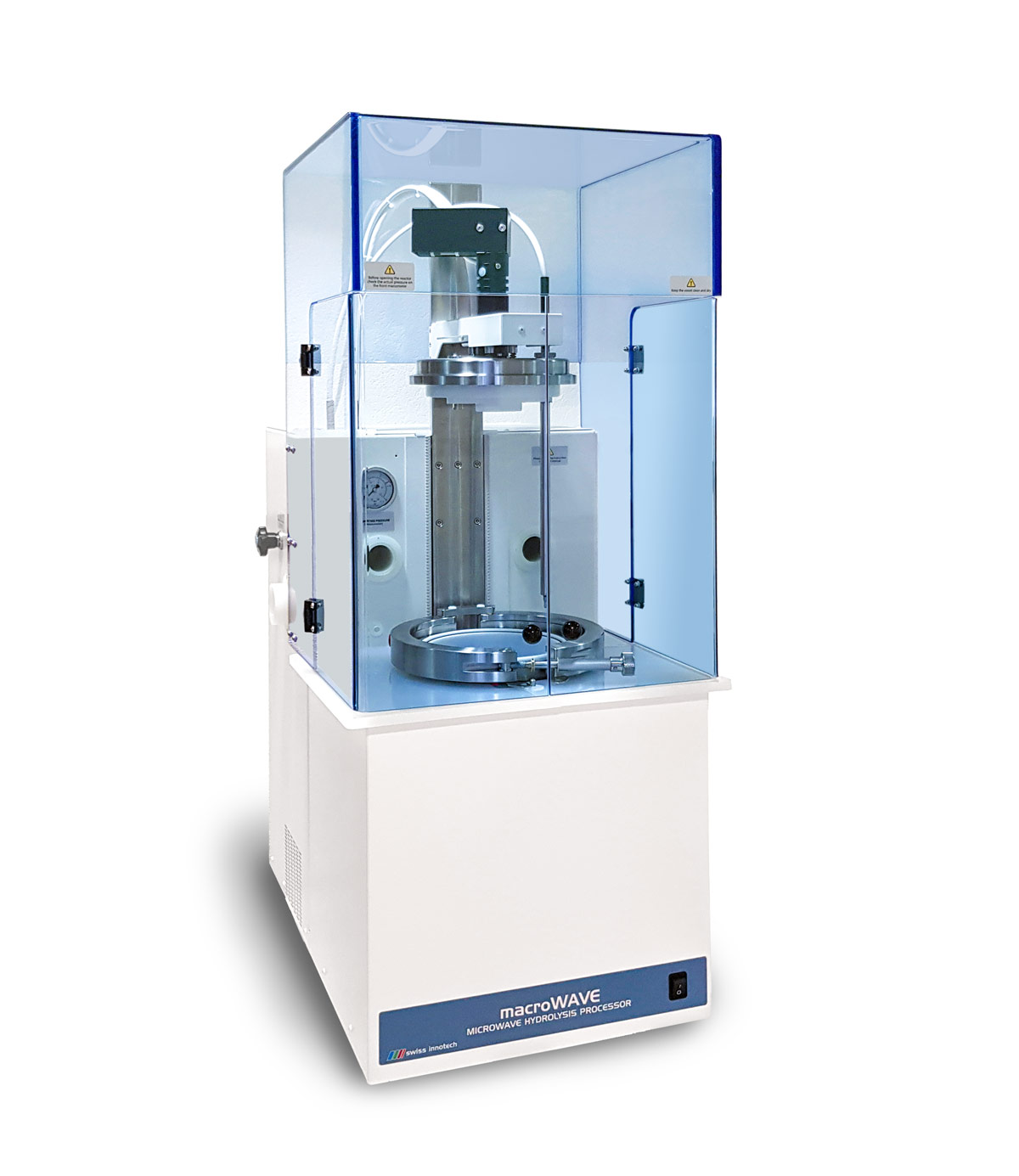

macroWAVE

SRC reactor for cleavage of peptide or protein chains

» protein hydrolysis in a few minutes «

Conventional devices for sample hydrolysis are often a time-consuming process. Our microwave hydrolysis in the SRC Reactor speeds things up considerably. The use of microwave hydrolysis for the three classical processes leads to optimal control of the hydrolysis conditions. Best possible accuracy, reproducibility, speed and stability are the result of your protein hydrolysis.

SRC gas phase hydrolysis

if waiting is no option

The time saved by using macroWAVE is enormous in protein hydrolysis as well as in other areas. Our SRC reactor helps accelerate the process of hydrolysis with microwave technology and pressure. Many other advantages, from precise repeatability to better accuracy, make your daily work easier. Instead of running the digestion reactions overnight, our SRC reactor can achieve comparable or better results in minutes.

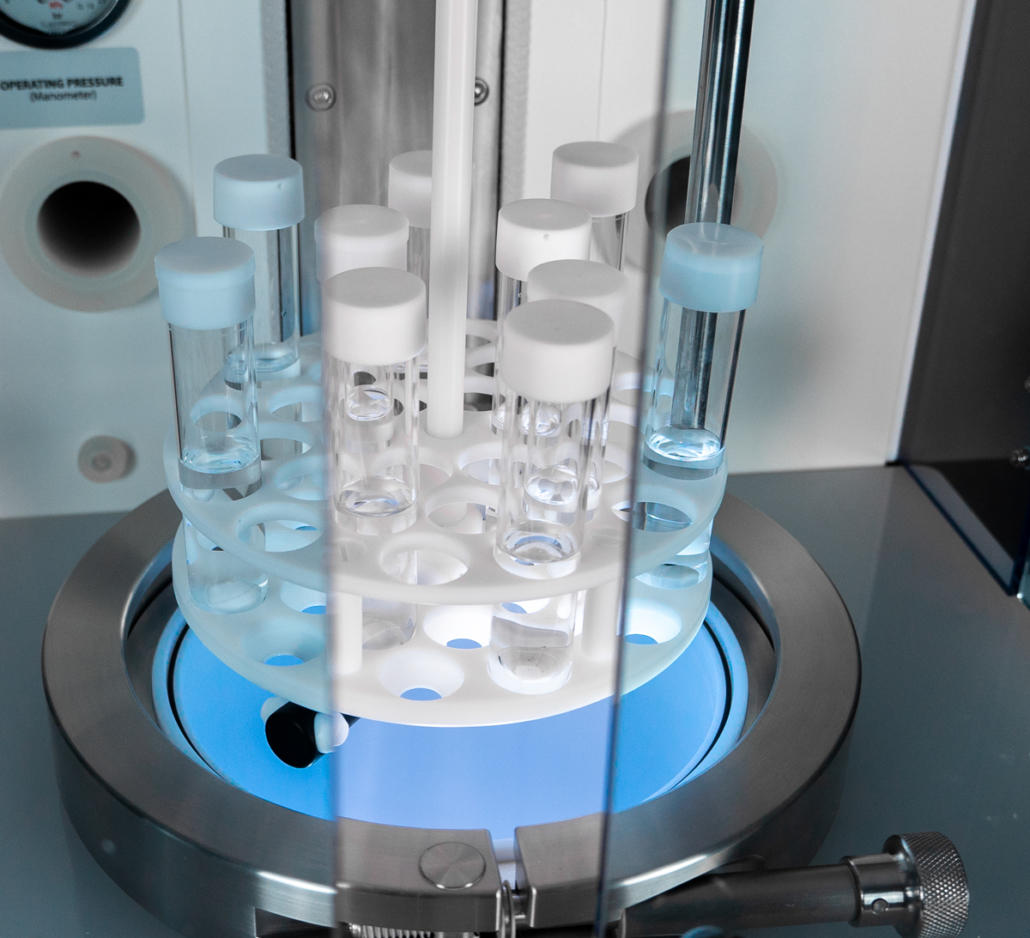

This increases the digestion efficiency impressively. Especially with hydrophobic proteins, the time advantage is greatest. Up to 30 samples can be used in one run, which means that an extremely high sample throughput can be realised.

SRC liquid hydrolysis

cleavage in perfection

Protein hydrolysis with macroWAVE enables one of the fastest and most reproducible cleavage of peptide or protein chains on the market. The hydrolysis time can be reduced from several hours to minutes. In addition, you get a more homogeneous and controllable result and need fewer tools and instruments.

All peptide compounds of a protein chain can be cleaved – the resulting free amino acids can be quantified by amino acid analysis. The proteins can be isolated from food and feed (meat products, dairies, agriculture and beverage industry), from living organisms (pharmacy, biotechnology…) or for diagnostic purposes, from blood and other human and animal samples.

fast facts

– rapid and reproducible cleavage of peptide or protein chains

– short hydrolysis times in a few minutes instead of several hours

– high sample capacity of up to 30 samples at a time

– higher homogeneity thanks to large sample volume and stirring in all samples

– possibility of gaseous or liquid hydrolysis

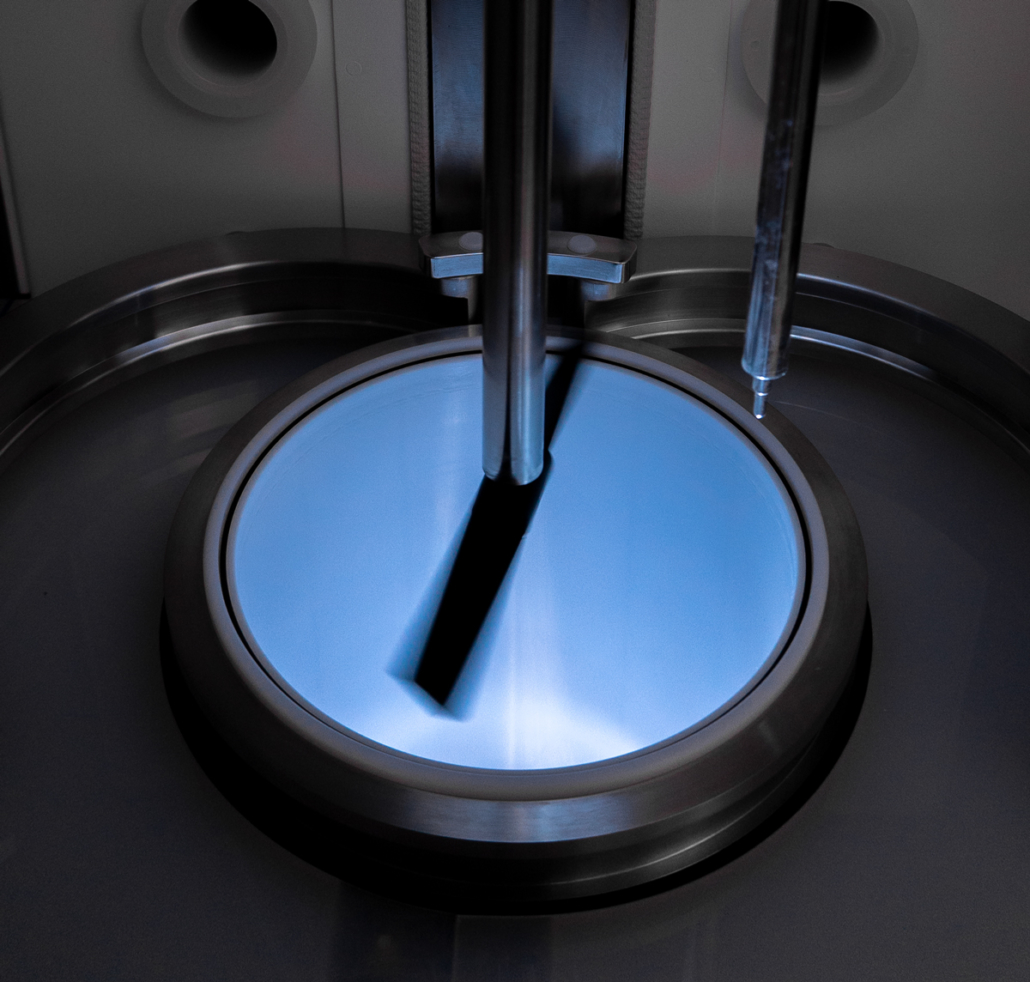

– Working pressure up to 18 bar and temperature above 200 °C

– identical conditions due to proven reactor technology

– simple operation thanks to control terminal with touch screen

– significantly faster processes under controlled conditions

– improved repeatability through monitoring of all relevant process parameters,

procedures, curves and method views

– very fast cooling of samples enables optimal output

– high-performance reactor for single and parallel reactions under identical conditions

– effective stirring in all sample containers due to protected magnetic drive

– controlled charging pressure under inert, reaction or protective gas

– optimal for hydrothermal reactions with highest requirements

– sample chamber can be purged with reaction gas

– Controlled pressure release after the end of the reaction prevents foaming over

– Existing overpressure valve prevents unexpected pressure increase

– other stirrers, holders and sample container versions available on request

email us for more information